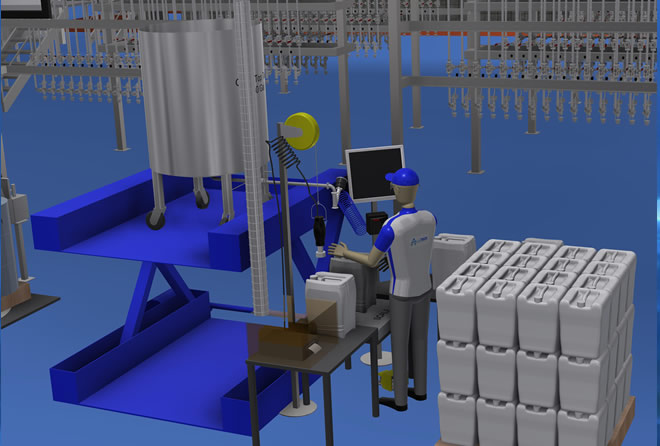

We are a one-stop lean engineering solutions company specializing in world-class batch manufacturing.Our expertise includes all aspects of the plant from MES to shop floor devices.

Our projects range from a simple dispensing valves to providing end-to-end design-build services utilizing our proprietary Factory Designer powered by iniTECH AI.