Your Digital Backbone

Streamline Efficiency with Bidirectional Digital Integration

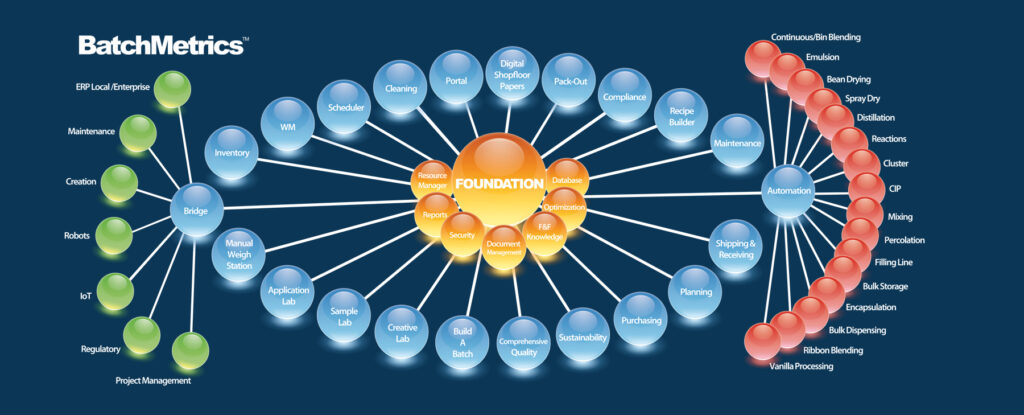

BatchMetrics is able to electronically integrate information from manufacturing environments and creative labs, exponentially improving efficiency. Instead of multiple layers that partially communicate with each other, BatchMetrics electronically connects the supplier, internal supply chain, and customer in one intuitive system.

BatchMetrics is not a reporting level; it is a fully integrating internal supply chain solution linking creation, regulatory and ERP. Its digital formulation controls and reports every touch- point from the time a batch is released to when it is shipped out the door.

Configured for You

Tailored Solutions for Every Plant in Every Industry

How is BatchMetrics different from other software solutions? We are the only software suite that is specifically designed for the food, flavor, fragrance, and beauty care industries. As opposed to other software solutions that force customers to adapt to their premade programs, we customize our software for each customer in order to fit specific needs. Thus, we do not require our customers to adapt to our software. Rather, we adjust to adapt to each customers’ needs. We understand standard operating procedures and flow on the plant floor, as well as how to comply with the new Food Safety Modernization Act.